TECHNOLOGY-VIGILANT

At SYNACTIC, we constantly upgrade our equipment to be on par with the latest in the manufacturing and technology needs. This yields ready-to-use quality products that are delivered quickly and affordably.

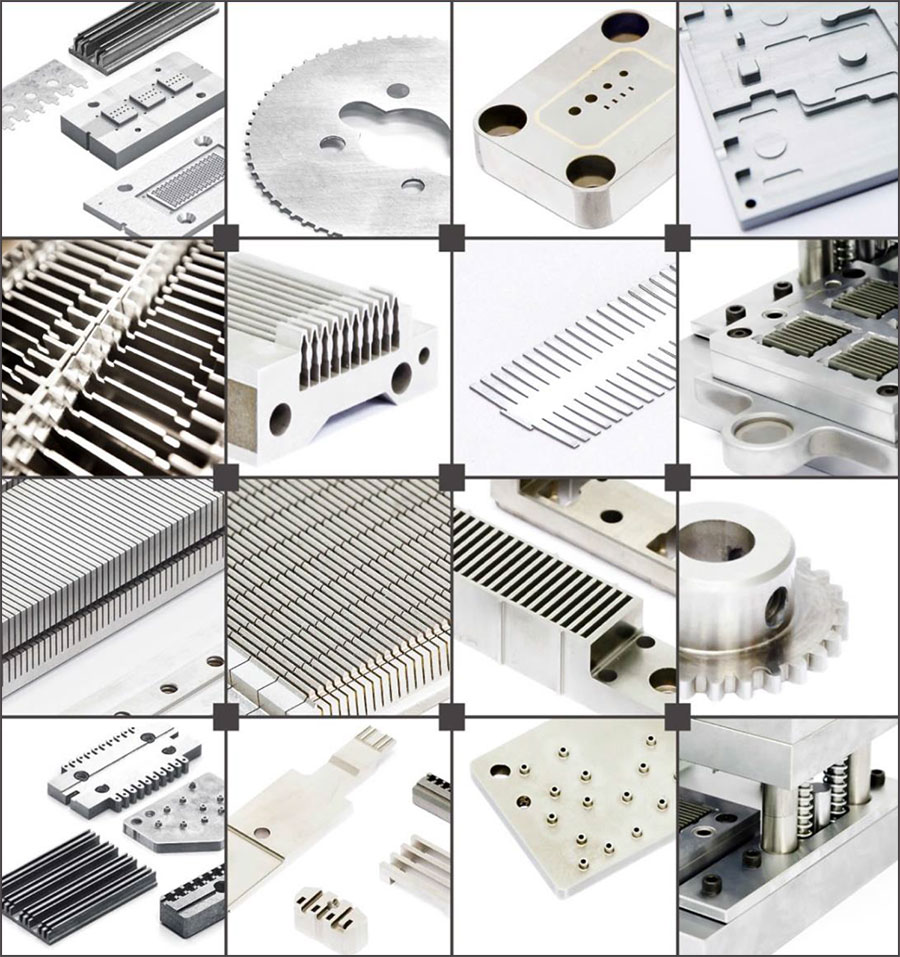

Precision Tooling Capability and Capacity

| CNC Milling Machines Centre | |

|---|---|

| “BROTHER”(Accuracy = 5um)

Compact Size Specification - 350mm x 250mm x 550mm

|

66 units |

| OKK (Accuracy = 5 um)

Size Specification - 600mm x 400mm x 500mm |

2 units |

| FANUC (Accuracy = 5 um)

Size Specification - 500mm x 400mm x 330mm |

4 units |

| FANUC (Accuracy = 5 um)

Size Specification - 700mm x 400mm x 400mm |

1 unit |

| YCM (Accuracy = 5 um)

Size Specification - 1020mm x 520mm x 540mm |

1 unit |

| AWEA (Accuracy = 5 um)

Size Specification - 500mm x 400mm x 400mm |

1 unit |

| MAZAK (6 AXIS) – INTERGREX J-200 (Accuracy = 5µm)

Size Specification - 700mm x 400mm x 480mm (36 Pot) |

1 unit |

| DMG MORI CMX 50U (3+2 AXIS) – CMX 50U (Accuracy = 5µm)

Size Specification - 500mm x 450mm x 400mm (36 Pot) |

1 unit |

| CNC Auto Lathe Machines | |

| TORNOS (Accuracy = 20um)

Size Specification - 195mm Max part length, 23mm Max Bar |

1 unit |

| CNC Turning | |

| YCM (Accuracy = 5 um)

Size Specification - 150mm x 345mm, 8” Chuck |

1 unit |

| Wirecut Machines | |

| Mitsubishi (Accuracy = 3um)

Size Specification - 380mm x 250mm x 250mm

|

10 units |

| CNC EDM | |

| Mitsubishi (Accuracy = 5um)

Smallest Specification - 300mm x 200mm x 200mm |

4 units |

| AD Spark (Accuracy = 10um)

Size Specification - 380mm x 250mm x 250mm |

1 unit |

| Super Drill | |

| OCEAN

Size Specification - 350mm x 200mm x 200mm |

3 units |

| Milling Machines | |

| Eumega (Accuracy = 25um) | 3 units |

| Manford (Accuracy = 25um) | 2 units |

| Pinnacle (Accuracy = 25um) | 1 unit |

| Toong Chi (Accuracy = 25um) | 1 unit |

| Lathe Machines | |

| Charles (Manual) (Accuracy = 20um) | 1 unit |

| Grinding Machines | |

| Chevalier (Accuracy = 2um) | 2 units |

| Linear (Accuracy = 2um) | 1 unit |

| Okamoto (Accuracy = 2um) | 8 units |

| CNC Grinding | |

| Chevalier Smart CNC Grinding (Accuracy = 2um) | 1 unit |

| General | |

| Laser Welding Machine (OR) (Focus Diameter =0.2-2.0mm) | 1 unit |

| Tapping Machine | |

| King | 2 units |

| West Lake | 1 unit |

| SPM Machine (Special Product) | |

| Water Jet | 1 unit |

| Auto Polishing | 2 units |

| Drilling Machine | 2 units |

| Sand Blast Machine (Rotowell) | 4 units |

| Auto Sand Blasting Machine | 2 units |

| Auto Hairline Texture Machine | 1 unit |

| Tumbling Machine (Techno) | 1 unit |

| Laser Engraving (Pump Laser Marker Series) | 2 units |

| Belt Sander (ALTE) | 1 unit |

| Bandsaw | |

| Dewalt | 1 unit |

| TYC | 1 unit |

| Jiu Chun | 1 unit |

Quality Assurance |

QA Equipments

We follow a stringent quality and production flow chart that assesses the goods in progress at every stage of fabrication from receiving the voice of customer to delivery and service. Our eye for Quality and our determination for continual improvement drive us to provide ever more innovative and cost effective solutions for our clients.

QA Measuring Equipments

- Werth Scope Check 3D CNC Machine (CMM)

- (Contact & Non-Contact) (Accuracy = 2um)

- (Measuring Ranges: 400mm x 200mm x 200mm)

- Mora Primus (575)(CMM)

- (Contact) (Accuracy = 1.3um)

- (Measuring Ranges: 500mm x 700mm x 500mm)

- Werth Vision Measurement Machine (Accuracy = 2um)

- (Non-Contact) (Accuracy = 2um)

- (Measuring Ranges: 300mm x 200mm x 100mm)

- Digital Caliper

- Digital Indicator

- Digital Micrometer

- Height Gauge

- Force Gauge

- Coating Thickness Gauge

- Drop Gauge

- Pin Gauge

- Tungsten Carbide Block Gauge

- Micro VU Spectra Profile Projector

- Deltronic Profile Projector

- Granite Surface Plate

- Depth Micrometer

- Microscope 50X

- Magnifying Lamp

- Surface Roughness Tester